Casting is one of the best examples of how improved technology can help in making things easy for humans. Current time, technologies, and science are making much more advanced things for humans. Precision die casting would have never been possible in the early past when people didn’t know about these things. There are several companies, that are using high-tech machines for providing casting services to customers. These technologies have the potential of making any material change into the shapes, a customer is willing to get.

What is die casting?

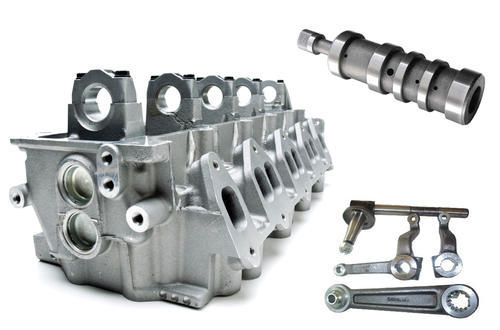

Casting refers to making any material lose its shape and changes to the shape clients want to get. It is done by putting high pressure on the material and running through several other processes to get the desired shapes. Precision die casting provides help in making sure that the material that has been finished after the casting services is long durable. It helps to generally make the material stronger and ready to be used in hard situations.

What is the process involved?

There Are generally five steps involved in getting the final product customers are looking to get. Each of the steps is important and done with proper care and monitoring. It is because, the steps are important and failure in any of them can lead to bad outcomes. The process involved is listed below:

- Clamping: Generally, this process helps to die the two separated clamped together. To do this, enough force is put in so that the metal which is being injected in between remains strong and can hold it.

- Injection: The metal which is put inside the material is molten. The transfer of this metal depends on the process that is being chosen. The two casting methods are in the process, that is the cold chamber and hotter chambers.

- Cooling: Once the above two steps are over, the metal is left to be cooled. So that, the material becomes much durable.

Similarly, several other processes include in the complete procedure of the casting. This whole process cannot be done alone without the help of human laborers. Machines need to be held and provided guidance for the proper working. If you are willing to get such services, you can get in touch with the market experts of the casting. The experts can help you choose the material, and give you quality in getting the best-finished product.